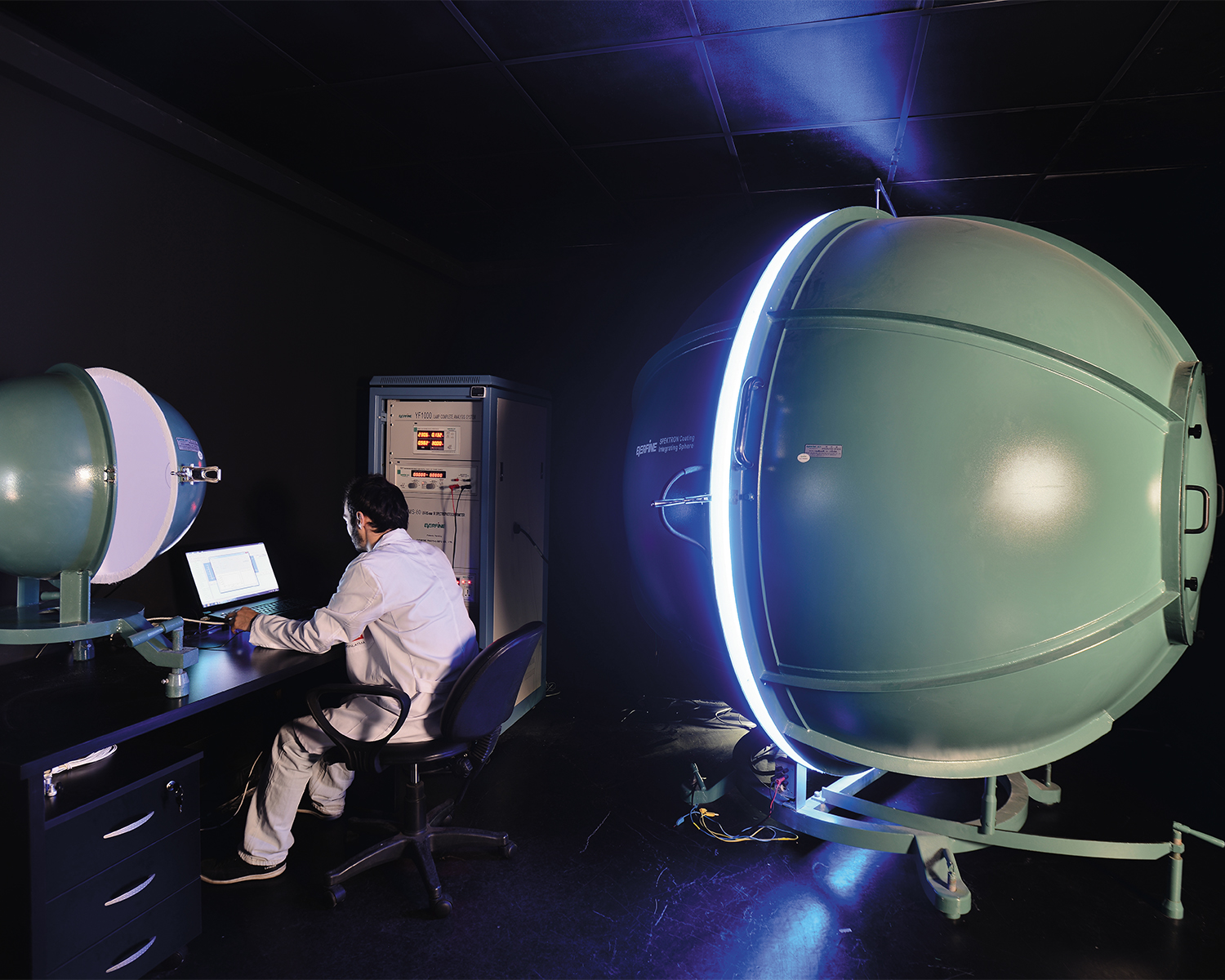

Developments in lighting technology have shown that light cannot be expressed only in numbers and its perception must be created. The fourth dimension in architecture requires experts to work with the right lighting fixtures. EAE Lighting laboratories are designed both to design high quality lighting equipment and to use product safety features.

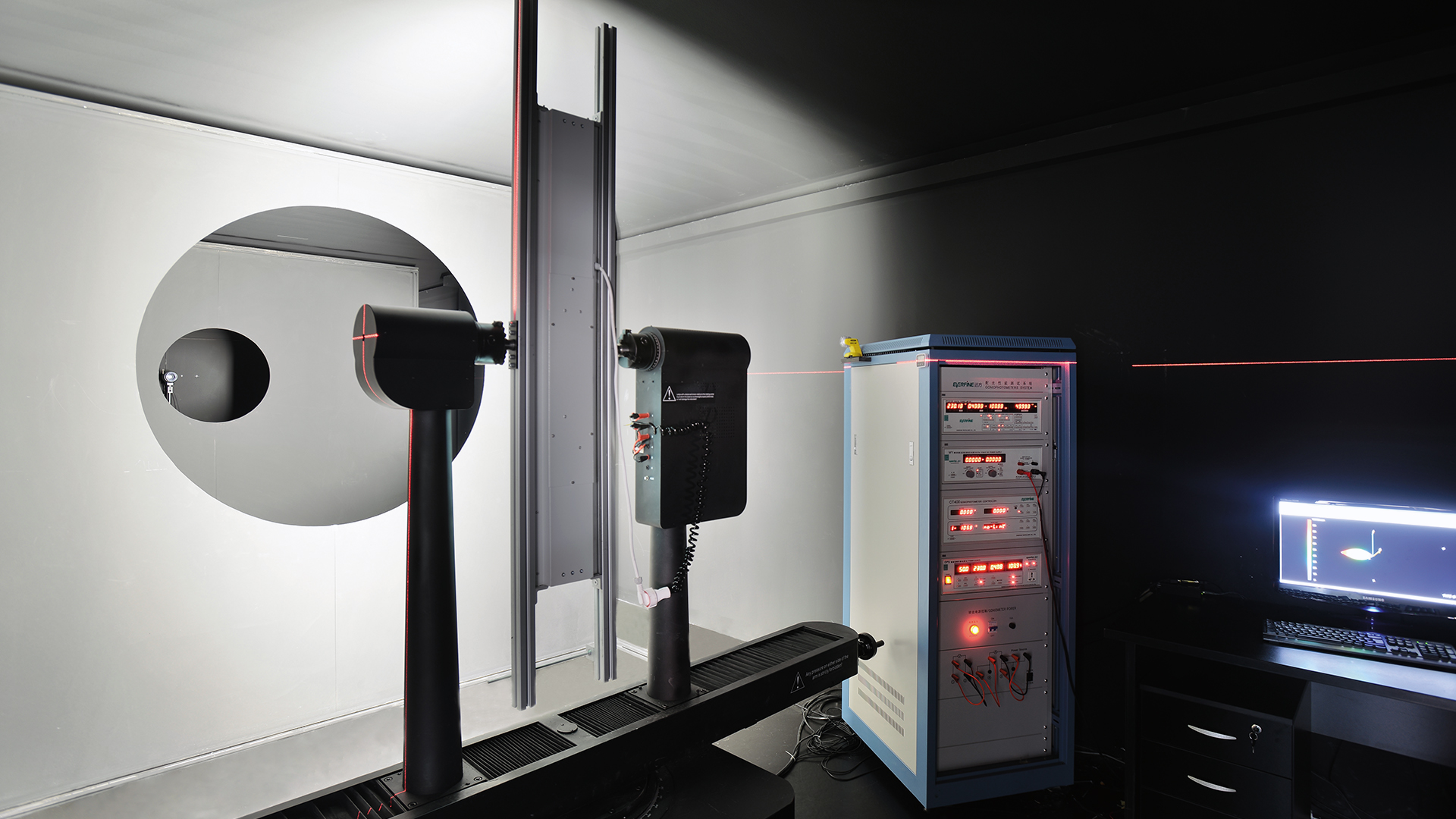

Goniophotometric measurements started to be made within the company in 2011.

Goniophotometer device; In the lighting fixture design process, it extracts the light distribution curves, measures the total lumen and glare values and gives ISOLUX-ISOCANDELA diagrams.

* TESTS ARE MADE ACCORDING TO EN (CIE) and IESNA STANDARDS.

Today, all tests, including SMT, that is, subsequently audited manufacturer tests of lighting fixtures, are carried out by EAE Lighting.

As a result of the tests, all certification is carried out by DEKRA.

In addition, laboratory team members are certified by KEMA (DEKRA).

EUROPEAN RULES

Achieving safer lighting solutions is possible by subjecting the luminaires to tests on different subjects. With these tests gathered under European rules EN 60598-1, EN 60598-2, EAE Lighting fixtures pass tests on more than 20 different subjects.

- Temperature Rise

- Humid environment

- Soil Continuity

- Leakage Current

- Torque

- Suspension Sets Safety

- Physical Impact

- Resistance to Electric Shocks

- Insulation Ranges

- Corrosion Tests

- Suspension Sets Safety

- Physical Impact

- Resistance to Electric Shocks

- Insulation Ranges

- Corrosion Tests

- Temperature Rise

- Humid environment

- Soil Continuity

Safety tests of electronic drivers, which develop with LED technology, are carried out in EAE Lighting laboratories under the scope of Driver safety standard EN 61347-2-13 and under the supervision of DEKRA..

CE-LVD All tests of the 'Low Voltage Directives' constitute a direct infrastructure for European certification.